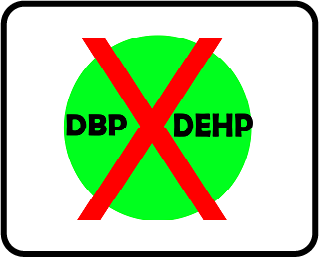

DBP AND DEHP FREE

Both Diethylhexyl-phthalate (DEHP) and Dibutyl Phthalate (DBP) are phthalates. Phthalates are plasticizers that are added to plastic materials to make them softer and more flexible.

Because phthalates are not chemically bound to the material they are added to, they can be released from the products that contain them, for instance into water and air. Emission of phthalates occurs during all the stages of the lifecycle of a product from production, through use, to disposal.

There is public concern about phthalates because of their widespread use and occurrence in the environment as well as their potential effects on human health. The US FDA is asking manufacturers to reformulate products containing DBP and DEHP excipients to cut the risk of toxicity.

There is more information in FDA’s article: Guidance for Industry; Limiting the Use of Certain Phthalates as Excipients in CDER-Regulated Products.

WHY PHTHALATES CAN NOT BE ADDED TO 3D PRINTER FILAMENT MATERIALS?

Since PLA is brittle and vulnerable to humidity, some filament manufacturers added phthalates to PLA material as an easy and low-cost approach to reducing the fracture. We considered it extremely dangerous since the printer hot-end heat the filament to melt during printing and the process also vaporizes phthalates into the air. Therefore, the operators were exposed to the risk of inhaling the toxic air.

To deal with fracture issues, we add non-phthalates and toxic-free based additives to improve the performance and lifespan of PLA filament. Due to the biodegradable nature of PLA material, it is recommended to store the filament in a sealed plastic bag or box after each print. In case the filament got damp, you can bake it in an oven at 50-degree celsius for about an hour to restore its dryness.

REFILL PACKGING TECHNOLOGY

Many of our customers complained about how to deal with their empty spools and asked if we could recycle them. This is a common issue for most of the 3D printing enthusiasts and to recycle the empty spools seems not feasible because of the transportation costs and the possibility to resale them. The piling up of spool not only is a waste of resources but also cause environmental pollution problems.

To solve this issue, we decided to develop the technology of refill packaging with the idea that users can refill their empty spool when they used up the filament. We spent a lot of effort in developing this technology since it is very tricky to wind a filament roll without spool. However, we think it is worthwhile because of the huge benefits both for consumers and the environment.

THE BENEFITS

1. Protect the environment; reduce usage and littering of plastic materials.

2. Reduce spool costs for consumers and increase re-salers competitive advantages.

3. Save packaging volume that also reduces transportation and storage costs.

4. Reduce the possibilities of filament fracture and breakage.

This is our new finding in our R&D lab. When we wind filament on a normal spool, the process causes a lot of stress on the filament during fast pulling and winding. There is no way for the stress to release before using the filament. Therefore, continuing pressure inside the filament causes the PLA filament fracture issues even worse. With our refill packaging technology, the filament roll was removed from the reel of the winding machine and the stress was released at the same time. In our observation, stress relief will largely reduce the fracture problems.

Friendly Links :

Copyright © 2015-2018 Shenzhen Color Rich 3D Technology Co., Ltd..All Rights Reserved.

online service